Precision Granite Products

Overview

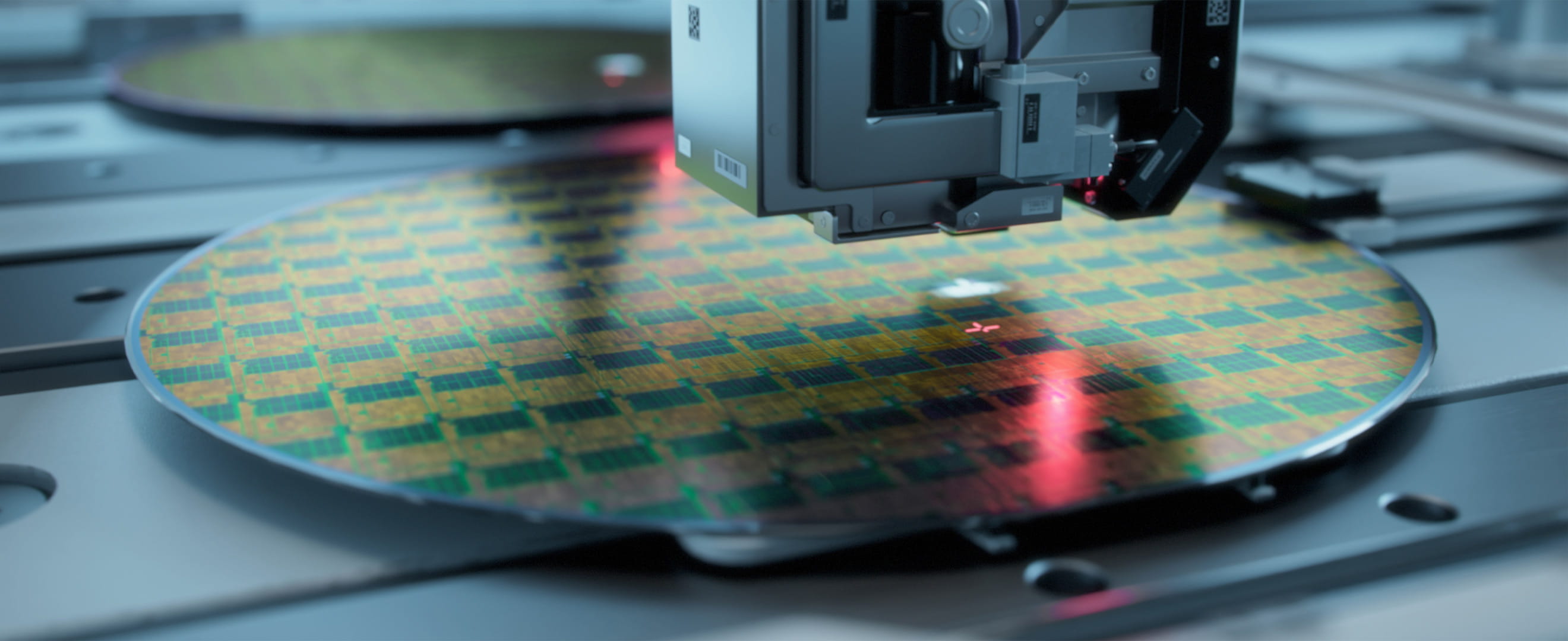

We maintain the top market share in the industry in the manufacture of large stone machine bases, which are indispensable for the manufacture of liquid crystal displays, semiconductors, laser processing machines, etc. Boasting ultra-high precision processing of 1/10000 mm, we have equipment to build quality products, such as a constant temperature booth with a temperature accuracy of ± 0.1°C, and a clean room class of 1000.

Products

We perform the entire assembly in a precision air-conditioning environment, to enable shortened delivery times and reduced costs.

We correspond to special products such as large products over 8 meters. We promise ultra-high precision quality.

A crane dedicated to clean rooms that require strict cleanliness. We will propose the most suitable specifications according to your request.

Three Advantages

We have a factory dedicated to granite processing and assembly. It is equipped with constant temperature room (temp. 23 ± 1°C, humidity 50 ± 10%), constant temperature booth (temp. 23 ± 0.1°C) and abundant measuring equipment, and we can produce ultra-high precision products in submicron unit.

We have achieved various kinds of stone (granite) processing, focused on surface plate and machine base. We can also respond to various special processing including a hole processing (minimum φ 0.8mm) and groove processing (minimum 0.2mm).

Utilizing the grinding technologies and know-hows cultivated through all kinds of stone (granite) processing for standardized and custom-made products, we can also process high precision processing of special materials such as ceramics and quartz glasses, and composite materials.

Characteristics of Granites

| Abrasion Resistance | Granites’ hardness is 2 to 2.5 times more than cast iron and it has excellent abrasion resistance. |

|---|---|

| Thermal Conductivity | It has low thermal conductivity and precision surface is stable. |

| Anti-vibration Characteristics | The granite itself has anti-vibration characteristics. |

| Maintenance-free | There is no rust generation or corrosion, change over the years is minute. |

| No Effect from Scratches | Even if it gets scratched, it does not burr and maintains precision surface. |

| Low Static Electricity | The generation of static electricity is minute. |

Main Facilities

Transfer amount: X 4.2m × Y 3.5m × Z 0.8m

Table size: 2.5m × 4.0m, Gate width 3.25m

Process capabilities: Up to 1.4m height and 25 tons

Table size: 2.5m × 5m, Gate width 3m

Height: 1.5m, 5 other units

Maximum measurement dimension:

W1600 × L2000 × H1600 mm

Manufacturing & Passion

We have contributed mainly to the FPD (Flat Panel Display) industry, which requires very precise positioning, through making manufacturing equipment bases and surface plates. The high reputation of our customers is supported by the craftsmen who can be called "polishing masters" (a process that uses fine abrasive grains to shave the surface evenly little by little). They achieve sub-micron (1/10,000th of a millimeter) level of accuracy that cannot be achieved by machines alone.

Our lapping technology is not limited to stones. It is possible to meet the diversifying and sophisticated needs of ceramics and hybrids of stone and ceramics. We want to pursue greater precision and provide new value to the world. We aim to make use of our technology in various fields. If you have any manufacturing issues, please feel free to contact us.