Large-scale Machinery Products

Overview

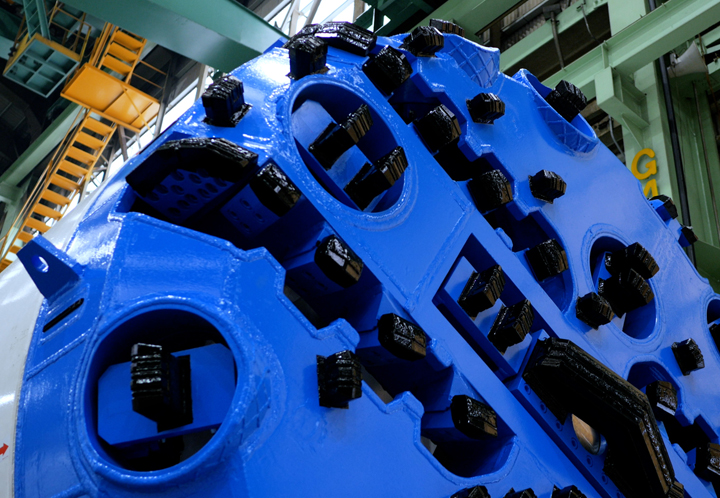

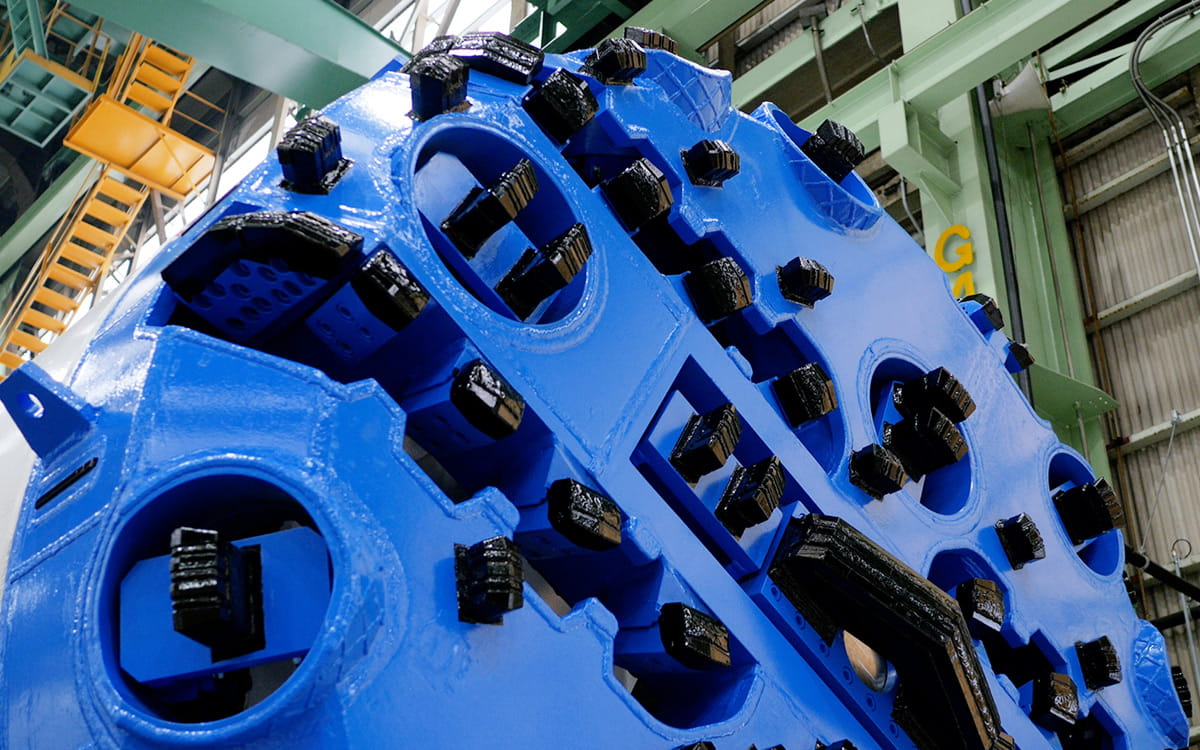

We manufacture custom-made ultra-large and high-precision products in niche areas through an integrated system from development, design, material procurement, manufacturing to after-sales service. We have the largest equipment in Chubu region, and our craftsmanship creates products that are difficult to standardize. We advocate "palace carpentry of industrial products". We have accumulated a track record of manufacturing a wide variety of one-off products, including tunnel boring machines (shield machines) that can handle outer diameters of up to 7 meters and have cultivated know-how over 50 years.

Products

Slurry type shield (for horizontal sectioning of rivers or seabed), EPB (Earth Pressure Balance) type shield (for urban civil engineering), TBM (Tunnel Boring Machine for hard rocks), etc.

Platform truck assembly and disassembly equipment, turnover equipment for thick boards, etc. (Corresponding to wide variety of factory equipment needs such as machinery manufacturing, repair equipment, etc.)

Special vehicles such as "bridge inspection vehicles / aerial work vehicles" applied crane technologies.

Specialized cranes such as tower cranes, gantry cranes, cranes for waste incineration plants which is using marine crane manufacturing technologies cultivated more than half a century.

Three Advantages

Since we provide an integrated system from development, design, production, installation, to after-sales service, we are able to create a wide variety of products, including one-off products and prototypes.

We have a track record and know-how in handling various special projects based on the technology and skills cultivated in the manufacture of tunnel excavators for more than half a century.

We have production lines and a painting plant for large products. They are fully equipped with top-class large-scale equipment in the Chubu region, including a five-sided processing machine. We have achieved technological high-value-added manufacturing.

Main Facilities

[Toshiba Machine]

Large machining that enables 5-axis machining by attaching a 5-axis head

Transfer amount: X 12.5m × Y 5.4m × Z 1.1m

Table size: 3.5m × 12m, gate width: 4.6m, height 3.65m

Process capabilities: Up to 40 tons of product weights

[Toshiba Machine]

Transfer amount: X 15.0m × Y 5.0m × Z 1.1m

Floor size: 4.0m x 4.0m x 3 tables (of one rotary table)

Height: 5.0m

Process capabilities: Up to 50 tons of product weights

Manufacturing & Passion

With a lifting height of 16.9 meters and a capacity for 100-kilogram-class welding, our factory is fully equipped to meet diverse manufacturing needs, such as large cranes and various processing machines. Our technicians’ craftsmanship can maximize these facilities to demonstrate our superiority in the production of large-scale products, especially for single items with strict precision requirements.

One of the motivations for young technicians is the in-house competition "Sekigahara Skills Competition" held every autumn. Divided into departments such as lathes, welding, assembly, and mechatronics control, they compete in speed and accuracy, and there is a lot of excitement on the day. This shows that the culture in which individuals improve their craftsmanship inherited from veterans and everyone competes with each other supports the technical capabilities of Sekigahara Seisakusho. No matter how much automation progresses, we will keep a mind of "machines are driven by human’s intention".