Hydraulic Equipment Products

Overview

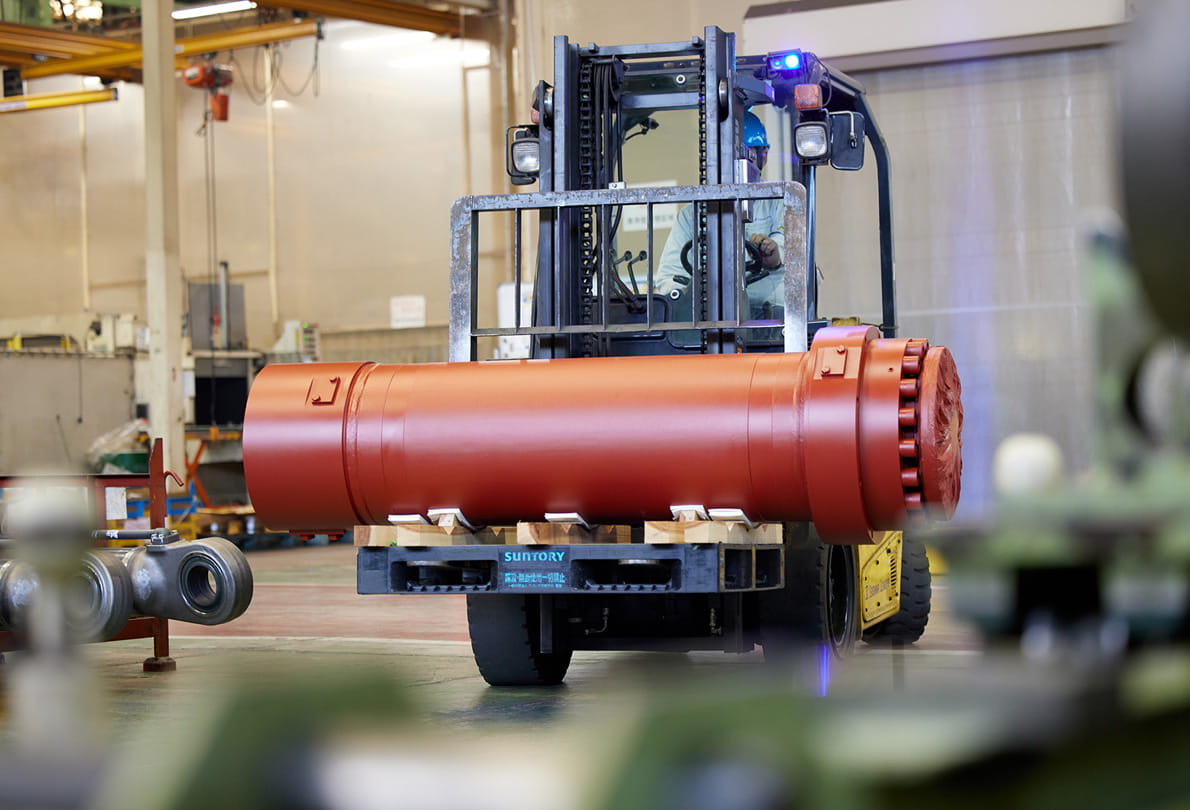

We have established a mass production system for large-scale mining equipment installed in mining machines. We timely supply various products to major construction machine manufacturers worldwide. Our integrated production system and refined core technologies meet customers’ expectations.

Products

- Various cylinders for excavators and wheel loaders

- Multistage cylinders for dump truck vessels

- Configuration: suspension, brake assemblies

- Class: 25 to 150 tons dump trucks

- Specialized cylinders for industrial equipment

- Cylinders for marine cranes

- Damper braces for base isolation structures

Three Advantages

We have core technologies such as SRB (Skiving and Roller Burnishing) technology which can finish processing the cylinder inner diameter in one shot, narrow-gap robot welding on the cylinder rod section, fully automated ultrasonic inspection.

We can produce with production lines of mass production to small lots, prototyping, and short delivery times. Our own strict inspection system enables to supply products with stable quality.

We combine our own product design and skilled processing technologies to produce special cylinders with high difficulty. We support our customers' high-precision manufacturing from the development stage.

Our Technologies

A processing method that uses a dedicated machine to perform skiving and roller burnishing at the same time. With the high production efficiency, you can get the benefits of delivery time and cost in cylinder manufacturing. The processing is done by engineers who know the mechanical properties and workpiece materials, so the finished surface is even and beautiful.

Main Facilities

Workpiece size (outer diameter): Up to φ450mm

Length: Up to 6180mm

Number of units owned: 2

Workpiece size (outer diameter): Up to φ450mm

Length: Up to 6180mm

Number of units owned: 10

Table size: Up to φ2000 mm (maximum processing diameter φ2500 mm)

Height: Up to 1800 mm

Number of units owned: 6

HMC table size: Up to 800×800mm

5-sided table size: Up to 4000×1200mm

Number of units owned: 10

Workpiece size (outer diameter): Up to φ1100mm

Length: Up to 4000mm

Number of unis owned: 23

Other: Various assembly and testing equipment (press, bench equipment, paint booths)

Manufacturing & Passion

No matter how much time and technology have evolved, Sekigahara Seisakusho places the utmost importance on "manual work" of people. Hydraulics manufacturing is no exception. From machining to welding and assembly, the manufacturing processes require a lot of craftsmanship, and we continue to improve our skills every day. There are Kaizen activities for "how to create quality with faster, higher precision, and at a lower cost". Bringing out wisdom through teamwork, Kaizen with positive suggestions, and making improvements, this accumulation of "human ingenuity" and "technology" has built the current Sekigahara Seisakusho. We will continue to create products that satisfy our customers working with colleagues, who are proud and passionate about our work.