Journal Box Products

Overview

We manufacture journal box products, which are important safety components for railway vehicles, for major bearing manufacturers in Japan. We have our own parker processing technology and boast a 90% domestic market share. We are proud that we can handle important safety parts, and we strive to ensure quality.

Products

* All of these products are journal box for railway vehicles for major bearing manufacturers in Japan.

We are involved in a wide variety of bearing products, and we are able to produce highly efficient and timely products while responding quickly to fluctuations in demand.

Three Advantages

Engineers who are familiar with the characteristics of materials and machines can respond to requests for high-precision forging and molding and difficult processing.

We are also good at parker processing and have equipped a line that applies the free hanger conveyor method. High productivity is achieved.

We can handle from a minimum of 1 lot. Taking advantage of our integrated production system, we deliver QCD that satisfies your request even in small lots.

Our Technologies

A processing method that produces a thin gray insoluble film mainly for the purpose of rust prevention, abrasion resistance, improvement of fatigue strength, and coating base. Since no electricity is used for the reaction, it is possible to process workpieces that are more complex than plating can. In addition, there is almost no dimensional change. We provide the optimal treatment according to the level of your request.

Manufacturing & Passion

The main products of our journal box products are important safety parts for railways that are related to safety and human life.

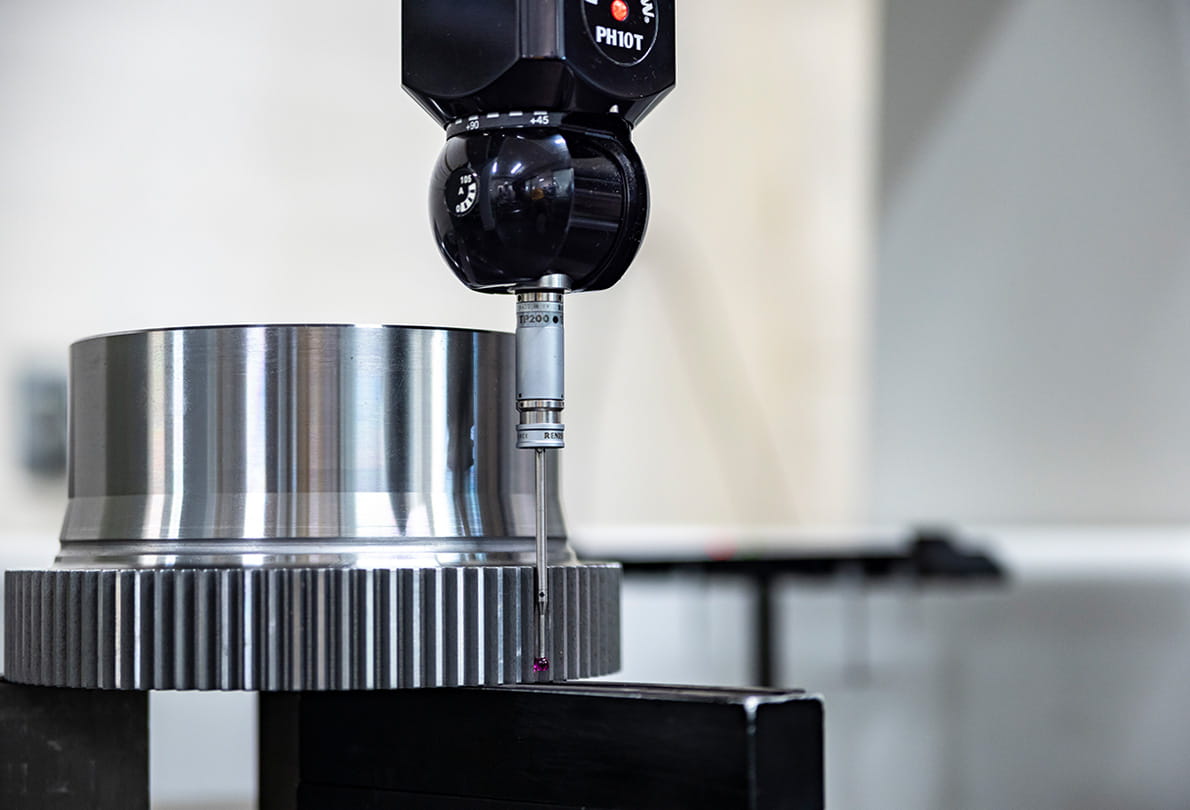

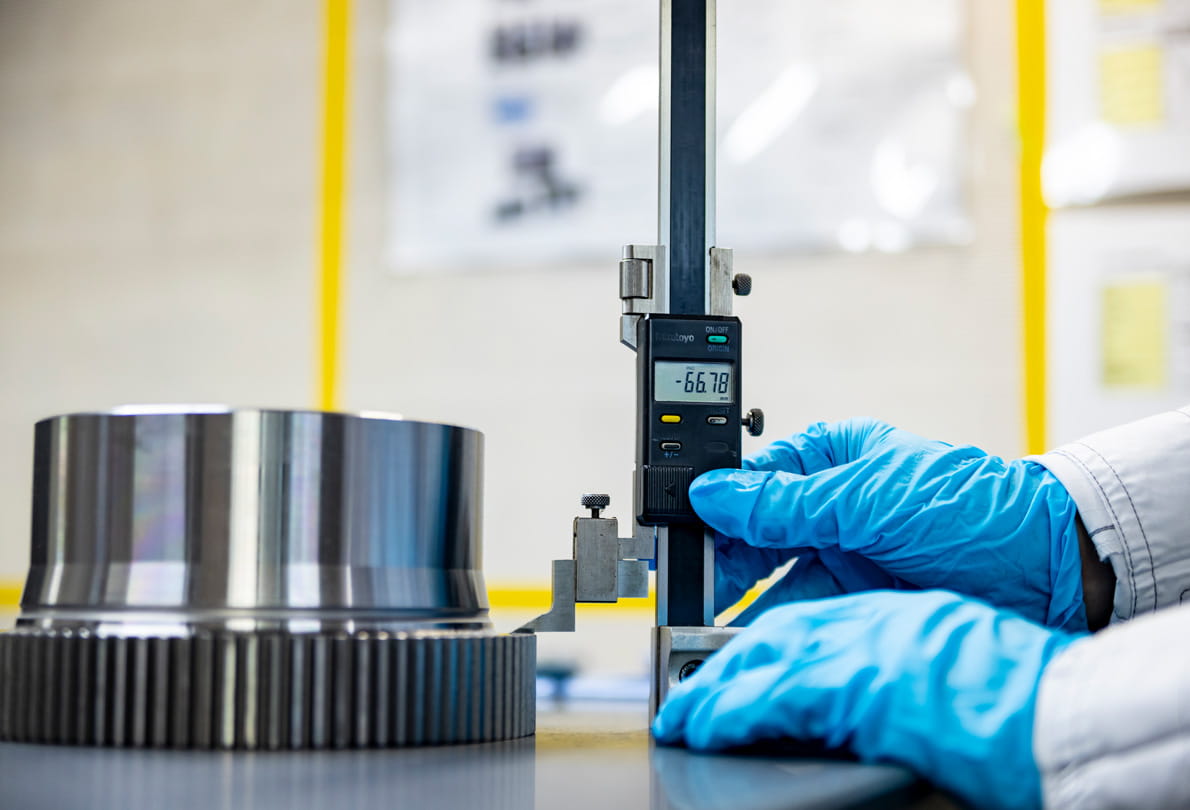

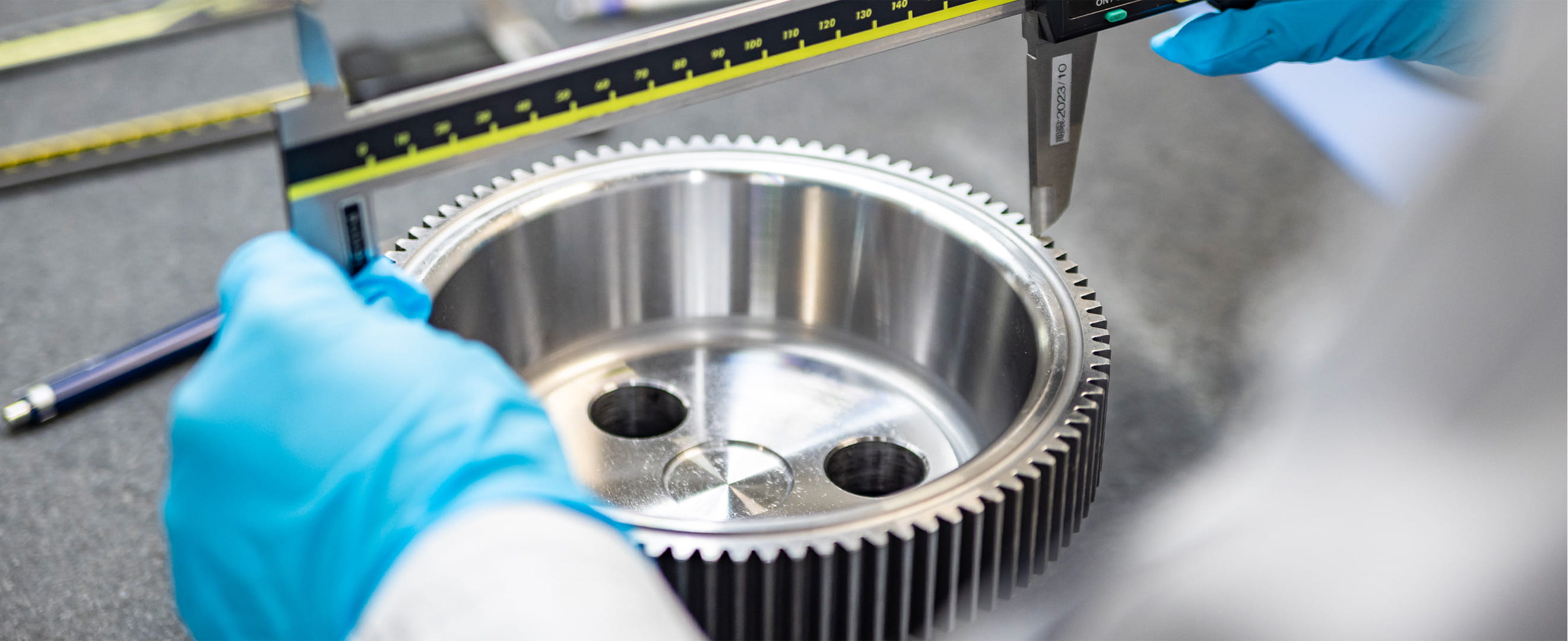

For this reason, we aim to "not make defective products or ship them", and we have built a thorough system for manufacturing from the parts level and well-prepared inspection system. We also use a dedicated machine that has the latest technology for inspections, however, we also perform double checks with our inspectors' eyes and hands, enabling more accurate quality control.

We might be like "unsung heroes" who pursue how to ensure quality. There is a lot of pressure, but every day I feel that my work is helping the world, and that makes it worthwhile.